Let’s Support Your Next Expansion

Whether you're building a new semiconductor fab, scaling battery cell production, or upgrading your test and QA labs, your workstations shouldn’t be the bottleneck. Treston helps facility and engineering teams move faster without compromising safety, compliance, or flexibility.

Here’s how we support your team from planning to installation:

Layout and Specification Support

Our team works with yours to understand your environment and workflow. We’ll help you develop optimized layouts with CAD drawings, part number lists, and integration recommendations to keep your buildout on track.

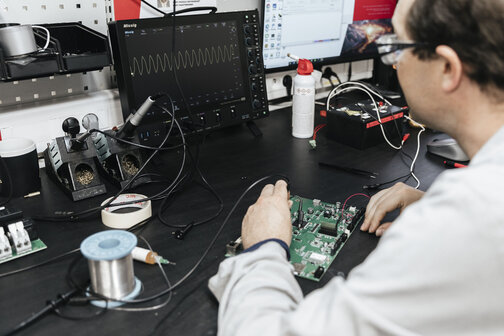

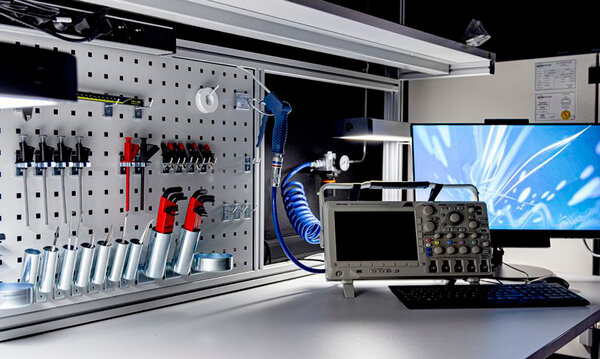

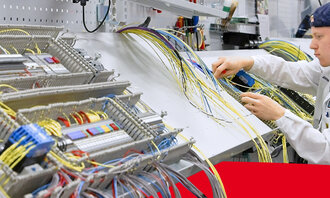

ESD-Safe, Modular Systems

All our ESD workstations are compliant by design, with protection built into every surface and frame. All Treston electronics workbenches utilize a modular construction that allows for seamless integration with test equipment, tools, and accessories at every stage of production.

Fast Delivery with QuickShip

No long lead times. Many of our most popular workstations ship in just 5 business days, making them ideal for fast-moving buildouts, pilot lines, or unexpected project changes.

Cleanroom-Compatible Options

We offer models that meet ISO cleanroom standards, built with smooth, easy-to-clean surfaces that resist contamination and particulate buildup. These are well-suited for wafer handling, diagnostics, and chip-level assembly.

Custom Solutions for High-Spec Environments

Have unique requirements? We’ll work with you to configure benches tailored to your needs, including special dimensions, material upgrades, or integrated power and tool management. If your process demands it, we can build it.