How Smart Mobile Stations Are Changing the Way Avionics Teams Work

Retooling a production or assembly process isn’t uncommon. But in a world full of workstations, it’s easy to assume every possible variation has already been designed. This story proves otherwise.

Two seasoned engineers faced very different workplace challenges. Each took a unique approach to solve their problem, and both arrived at the same solution: the Smart Mobile Station from IAC, A Division of Treston.

Case 1 – Supporting a FOD-Free Zone

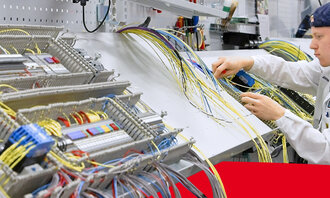

This case takes place at an avionics company in Southern California specializing in proactive maintenance and repair services. The objective at this facility was to strengthen Foreign Object Debris (FOD) prevention protocols by improving workstation design.

To support this goal, technicians needed workstations where every item—tools, components, work orders, pens, and notes—had a clearly designated place and remained visible at all times. These FOD-focused stations would exclude drawers or enclosed cabinets where items could be lost or forgotten, instead prioritizing open, visible storage that keeps the work surface clear and organized.

The Manager of Manufacturing Engineering initially set out to find compact, traditional-style workstations with added overhead storage to replace the need for drawers. After reaching out to IAC, he was invited to tour the facility and explore the demo showroom in person. He accepted the invitation.

A Surprising Find

During the facility tour, the IAC team brought the customer into the demo room, where a range of IAC benches and workstations were set up for hands-on exploration. As they walked through the space, one unit caught the visitor’s eye. He pointed and asked, “What’s that?”

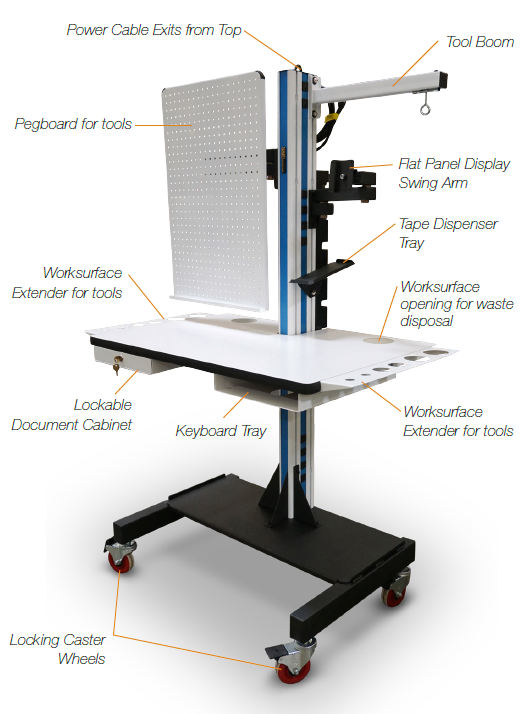

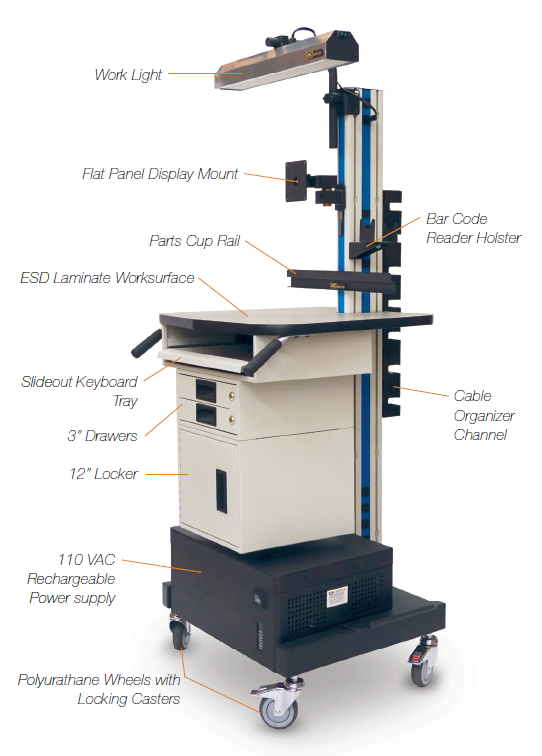

What he noticed was the Smart Mobile Station (SMS), a newer solution designed to combine mobility, organization, and flexibility in one compact footprint. It turned out to be exactly what he had been looking for.

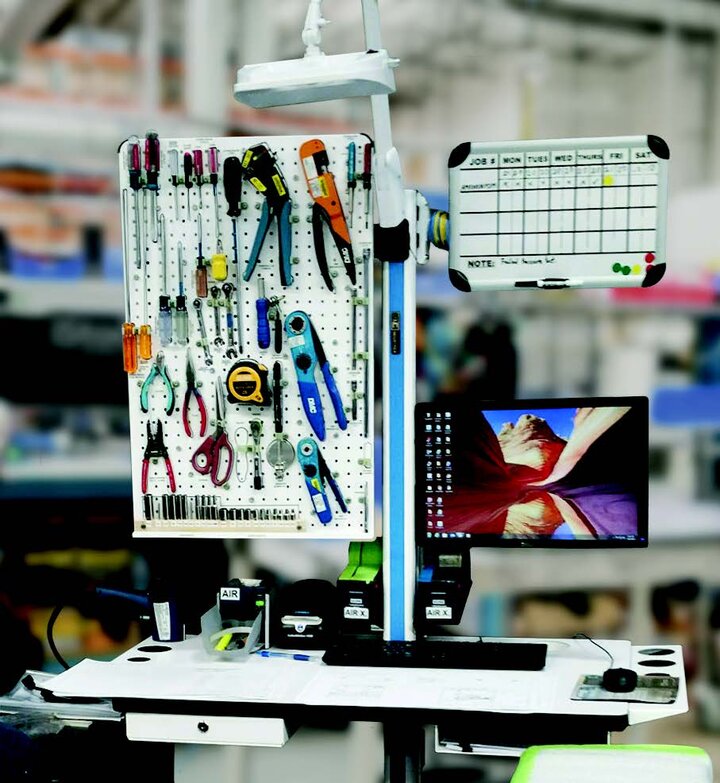

Working closely with IAC’s Sales Application Manager and Engineering team, a custom version of the Smart Mobile Station was developed to meet the facility’s FOD prevention needs. Modifications included a large pegboard with marked tool locations, a tool boom to support the customer’s job status board, and a suspended trash receptacle. The work surface was extended with storage rails on both sides for drills and other tools, and the power cord was rerouted to exit at the top, allowing for connection to overhead power drops.

The initial order was such a success that the facility ultimately transitioned all of their existing workbenches to Smart Mobile Stations.

Case 2: Solving for Space Constraints

At another avionics service facility located over a thousand miles away, a Service Program Manager faced a common but pressing challenge. Due to a facility consolidation, the number of technicians had nearly doubled—without any increase in available floor space.

The need was clear: find a compact workstation that maintained the same functionality technicians were used to. Since each technician required dedicated access to their own tools and computer, shared workstations were not an option.

This Program Manager was already familiar with IAC’s Dimension 4 (D4) workstations, which were in use at the facility. But as the space grew tighter, he began to explore more flexible alternatives to the traditional bench setup.

While reviewing options on the IAC website, he came across the Smart Mobile Station. The concept stood out. After conducting value stream mapping and process flow analysis to assess its fit, the team ordered powered SMS units for evaluation.

What They Learned

The Program Manager quickly saw the value of the Smart Mobile Station. Its compact footprint helped reduce workstation space per technician without compromising functionality. Equipped with durable polyurethane casters, each SMS could be easily moved throughout the facility, giving technicians access to their personal tools and equipment wherever the work takes them.

The powered model chosen included a rechargeable battery system that supplies 110VAC to computers and instruments. This eliminated the need for hardwired power connections and gave technicians full mobility during their shift. As the Program Manager noted, “The technicians with their Smart Mobile Stations move constantly throughout the shift.” At the end of the day, the units are rolled into a designated charging area and recharged for the next use.

This facility has since transitioned entirely to IAC’s Premium (powered) SMS units—no customization needed. As one end user put it, “We wanted our technicians to feel at home no matter where they were in the operation. The SMS allows them to access their workstation and computer at any location they’re working.”

Whether it’s reducing clutter in FOD-sensitive environments or maximizing space in high-demand facilities, the Smart Mobile Station is proving to be a versatile, technician-friendly solution. Its mobility, power options, and compact design make it a standout choice for modern work environments that demand both flexibility and efficiency.

IAC’s Smart Mobile Stations are being discovered as the surprise solution to many modern facility challenges, and have separated themselves out as a new class of workstation. Undeniably the most personal of workstations.

Ready to see if the Smart Mobile Station is the right fit for your team?