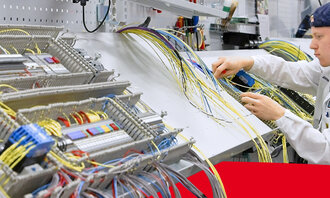

Visual Guide: Anatomy of an ESD-Proof Workstation

At Treston, we don’t just build ESD-safe workstations—we engineer them to be ESD-Proof by Design™. This means every component, connection, and material is intentionally selected and configured to prevent static build-up and protect sensitive electronics throughout the production process.

If you’re responsible for ESD compliance, product reliability, or production efficiency, understanding what makes a workstation truly "ESD-Proof" is essential. In this post, we break it down—visually and practically.

What Makes a Workstation “ESD-Proof by Design™”?

A compliant workstation goes beyond an ESD mat and wrist strap. It’s a complete, grounded system where every part—from the chair to the frame to the bins—contributes to static control. Here’s what it looks like in practice:

🟡 1. Common Point Ground (CPG)

The CPG connects the workstation and other grounded elements to the facility’s protective earth. This is the central hub where all ESD grounding cords terminate, ensuring any charge is safely dissipated.

🟡 2. Grounding Cords

Grounding cords run from the bench frame and floor mat to the common point ground. These cords create the path for charge dissipation, especially on benches that don’t self-ground via frame design.

🟡 3. Grounding Bolt Location (on Bench Frame or ESD Work Surface)

This is where the grounding cord attaches to the bench if the model does not self-ground through the floor. Grounding can be established through the ground bolt(s) in the ESD work surface or directly to the bench frame, depending on the model and setup. Both the top and frame are ESD-safe and can serve as grounding points to connect the workstation to the common point ground (CPG). It’s essential for ensuring proper continuity between the bench and the CPG.

🟡 4. ESD Chair

Chairs in ESD-protected areas must include conductive casters and static-dissipative materials. These features allow the operator to stay grounded through contact with the ESD floor, helping to maintain continuous protection against electrostatic buildup while seated.

Treston offers ESD chairs, trusted across electronics manufacturing environments for their durability, ergonomic comfort, and compliance with ESD safety standards. These chairs are designed to integrate seamlessly into an EPA and complement the rest of your static-safe workstation.

🟡 5. ESD Wrist Strap and Earthing Box

Operators wear wrist straps connected to an earthing box mounted on the workstation. This is one of the most direct and effective ways to ground a person while they handle static-sensitive components.

Many facilities choose to use constant monitors—devices that continuously check whether the wrist strap and ground connection are functioning properly. If a connection is lost, the monitor immediately alerts the operator or shuts down the workstation.

🟡 6. ESD Work Surface & Accessories (Including Bins)

The benchtop must be static-dissipative and properly grounded to ensure safe handling of sensitive electronics. Treston benches feature ESD work surfaces with integrated ground bolts for secure and reliable discharge paths.

All standard Treston accessories with “-49” part numbers are designed to be ESD compliant. This includes shelves, upright systems, bin rails, hanging drawer units, and more. These components are finished with ESD powder coating to ensure they meet the requirements for use within an EPA (Electrostatic Protected Area).

Why it matters: Every element in the workstation setup plays a role in ESD control. With Treston, you can be confident that both the core bench and its modular accessories meet the standards needed to protect your product and process.

🟡 7. ESD Garments and Footwear

Operators should wear ESD-safe clothing and shoes that help maintain their grounding when working on conductive flooring. Proper apparel complements wrist straps and flooring to create a comprehensive grounding system.

🟡 8. ESD Flooring

The flooring in an ESD Protected Area is critical—it must be conductive or dissipative and connected to the facility’s ground. This allows for grounding of personnel, benches, and even carts or chairs that come into contact with it.

Treston Advantage:

Some Treston benches—Concept and QuatreX—are grounded simply by placing the glides directly onto an ESD floor. Thanks to the ESD-painted steel frame, static flows through the glides to the floor, bypassing the need for an additional ground cord. For other frame types, the grounding bolt and cord system (as shown at #3) is used.

Grounded. Compliant. ESD-Proof by Design™.

Treston workstations are engineered for full-system protection—from frame to floor, and everything in between. Our “ESD-Proof by Design” approach means you don’t have to second-guess compliance. Whether you’re building a new EPA or updating an existing one, we offer trusted solutions that meet the strictest ESD standards.

Need help assessing your current setup?

Investing in ESD protection isn’t just about compliance—it’s a smart way to prevent costly repairs, product replacements, and potential damage to your brand reputation.

Try our ESD Savings Calculator to see the impact. Just enter a few key figures, and the tool will show your potential savings in real dollars. For expert insight into your specific setup—or to explore our ready-to-ship ESD Bundles for fast, compliant workstation grounding, contact us. We’re here to help.