Integrated Packing and Shipping Stations

Carissa Harris

Traditionally, fulfillment centers have utilized two main workstations for order fulfillment – a packing station, and a shipping station – each workstation dedicated to a single process. A worker at a packing station stocked with packing material and void-fill machines will pack the order, then send it along to a worker at a shipping station who finalizes the order for shipment.

However, with an ever-growing need for faster speeds and increased productivity, many fulfillment centers are combining these processes into a single, integrated packing/shipping station – one station that can more efficiently complete both tasks.

In a typical packing station, you will find:

-

Shelves stocked with boxes and envelopes

-

Tape dispensers

-

Rolls of void fill or void fill machines

-

Cutting units, rolls of labels

In a typical shipping station, you will find:

-

Computer, keyboard, mouse

-

Scanner

-

Scale

-

Printer

Combining these stations into one complete pack and ship station can greatly free up space in your warehouse, while also simplifying the entire process and reducing the time it takes for products to get to the customer.

The key to an integrated pack/ship station is organization. Here are 4 tips to creating an efficient pack/ship station:

-

Utilize arm accessories to remove bulky machines from the work surface, while maintaining easy reach.

Machines, such as label printers, water-activated tape dispensers, void fill machines, can be kept within reach of the worker, while also keep the workspace clear for packing.

- Store packing materials above or below the workspace.

Packing materials should be easily accessible for the worker. It is important to always have a good supply of the necessary materials in the correct sizes, in order to avoid unnecessary wasted time. Add labels to make restocking a breeze.

-

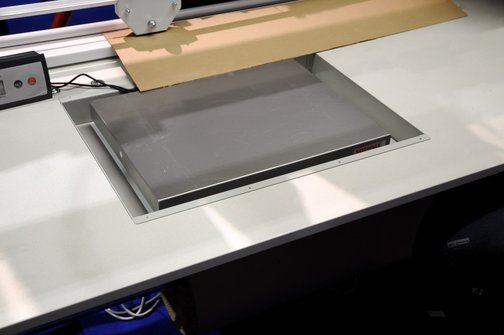

Inset your scale into the work surface.

This will maintain a clean workspace and improve the flow of the packing/shipping process. A scale table can also be added alongside the workstation.

-

Stations should be adjusted to fit the worker. Consider the height of the table, the height, and the distance of monitors and arm accessories. Evaluate the comfort of the worker to ensure they are not feeling the unnecessary strain.

There are a variety of benefits for integrating the order fulfillment process. An integrated station can be a great space-saver for any warehouse. The smaller required footprint reduces the costs for valuable real estate. There is also no longer a need to transport packages between packing and shipping stations. With fewer touch-points, there will also be a reduction in errors. Ultimately, the greatest benefit is the impact on productivity and efficiency, which is a key driver of customer satisfaction.

Integrate Your Packaging & Shipping Stations with Treston

Luckily, Treston offers several ways to get started on ordering packaging and shipping stations, and accessories. Design your own workstation with our virtual 3D experience or explore our smart workspace inventory to find lean, ergonomic solutions. When you're ready to take the next step and request a quote, either refer to our catalogs for ordering information or contact the experts at Treston to receive direct assistance.

About Treston

Treston offers a variety of ergonomic workstation products designed to improve workplace productivity. Each station is designed with the needs and comfort of the worker in mind. All Treston workstations are adjustable and adaptable due to their modular design. A custom workstation can be created from our vast range of standard accessories.

Treston has recently teamed up with IPG (Intertape Polymer Group) to design packing station accessories that support a variety of their market-leading, sustainable void fill products. These arm accessories move large, heavy machines from the work surface or from their floor stands and keep them within easy, comfortable reach of the worker.